In the pursuit of safety, efficiency, and reliability, engineers and industries have consistently sought innovative solutions in fluid control. Among the array of valve designs, It stand as a remarkable advancement. These valves, equipped with a flexible metallic bellow, have revolutionized the fluid control landscape by addressing critical concerns related to leakage, fugitive emissions, and maintenance issues. This comprehensive article will explore the fascinating realm of bellow seal valves, shedding light on their various types, myriad benefits, diverse usage, safety advantages, and the groundbreaking offerings of Freture Techno as a leading manufacturer in the field.

What are Bellow Seal Valves?

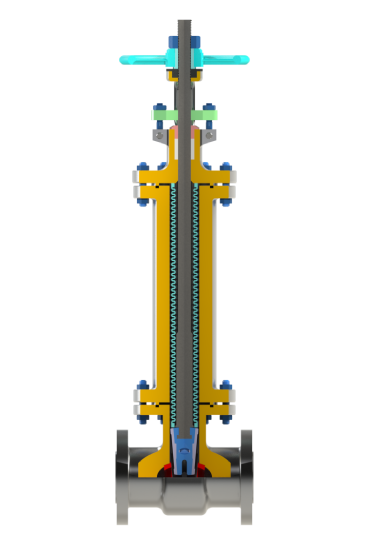

They are a specialized type of globe or gate valves that boast a unique construction. Unlike traditional valves, which use gland packing to create a seal around the valve stem, The feature a flexible metallic bellow. Typically made from stainless steel or other corrosion-resistant alloys, this bellow forms a hermetic seal around the stem, effectively preventing any leakage of hazardous fluids or gases.

Types

Bellow Globe Valves:

They utilize a bellow within the valve body to provide a reliable stem seal. These valves are ideal for applications where precise flow control and throttling capabilities are required.

Bellow Gate Valves:

Bellow gate valves use a bellow to seal the stem against the bonnet, offering excellent isolation when in the closed position. These valves are often preferred for applications requiring on/off control in high-pressure or high-temperature environments.

Benefits

Leak-Free Performance:

One of the most significant advantages of these valves is their ability to deliver leak-free performance. The flexible bellow ensures a tight and secure seal around the valve stem, effectively preventing the escape of hazardous fluids or gases. This feature is particularly critical in industries dealing with toxic or flammable substances.

Enhanced Safety:

Safety is of paramount importance in fluid control systems, especially in industries such as oil and gas, chemical processing, and petrochemicals. It play a crucial role in enhancing safety by minimizing the risk of fugitive emissions. Their reliable construction ensures that hazardous substances remain securely contained within the pipeline, mitigating potential risks to personnel and the environment.

Reduced Maintenance:

Traditional valves with gland packing require regular maintenance and adjustments to prevent leaks. It significantly reduce maintenance needs due to their self-adjusting nature. The flexible bellow compensates for stem movements, maintaining a consistent and effective seal throughout the valve's lifespan, thereby reducing downtime and maintenance costs.

Extended Service Life:

They are built to withstand the rigors of challenging environments, providing an extended service life. The metallic bellow's resistance to wear, tear, and corrosion ensures optimal performance even in harsh operating conditions, resulting in cost savings and enhanced reliability.

Usage

They find diverse applications in various industries due to their unique advantages. Some of the key areas of usage include:

Chemical Processing:

In chemical processing plants, they play a critical role in ensuring the safe handling and control of corrosive and toxic fluids. They prevent leaks, maintain process integrity, and protect personnel and the environment.

Oil and Gas:

They are extensively used in oil and gas facilities, where the handling of hydrocarbons demands high levels of safety and reliability. These valves are employed in pipelines, refineries, and petrochemical plants to regulate the flow of crude oil and natural gas.

Pharmaceutical Industry:

The pharmaceutical industry relies on this valves for their leak-tight performance, especially in handling sensitive and sterile processes. These valves are used in pharmaceutical manufacturing, biotechnology, and research laboratories.

Power Generation:

In power plants, this valves find application in steam and water control systems. Their ability to withstand high pressures and temperatures makes them suitable for critical functions in power generation.

Safety Advantages

Fugitive Emissions Reduction:

Fugitive emissions, the unintended release of gases or fluids into the atmosphere, are a major concern in various industries. They effectively minimize fugitive emissions, enhancing safety and environmental protection.

Sealed Stem Design:

The bellow seal valve's sealed stem design prevents the leakage of hazardous substances, ensuring the protection of personnel and equipment. This feature is of paramount importance in industries dealing with toxic or flammable materials.

Compliance with Industry Standards:

They are designed and manufactured to meet stringent industry standards and safety regulations. Their compliance ensures that they meet the necessary criteria for safe and reliable operation in various applications.

Freture Techno: Leading the Bellow Seal Valve Innovation

As industries demand cutting-edge solutions for fluid control challenges, Freture Techno stands as a beacon of excellence. As a leading manufacturer of bellow seal valves, Freture Techno incorporates state-of-the-art technology and unwavering dedication to safety and reliability.

Advanced Materials:

Freture Techno utilizes premium-grade materials, such as stainless steel and corrosion-resistant alloys, to construct these valves that endure harsh operating conditions and maintain leak-free performance.

Precision Engineering:

With a focus on precision engineering, Freture Techno ensures that its valves adhere to the highest industry standards. The company's commitment to excellence guarantees optimal performance and reliability.

Recognizing that each industry has unique requirements, Freture Techno offers customizable solutions to meet specific demands. It can be tailored to fit a wide array of applications seamlessly.

Compliance and Certifications:

Metal Bellow valves comply with various international standards and certifications, providing customers with the assurance of safety and performance.

They have emerged as a revolutionary force in the world of fluid control, offering leak-free performance, enhanced safety, reduced maintenance, and extended service life. These valves find diverse applications across industries that prioritize safety and reliability, such as chemical processing, oil and gas, pharmaceuticals, and power generation. As a leading player in the field, Freture Techno continues to innovate and deliver cutting-edge solutions that exceed industry expectations. Embracing the brilliance of Bellow Sealed Globe/ Gate Valves is a step towards enhancing safety, efficiency, and environmental responsibility in fluid control systems, paving the way for a brighter and more secure future.